A Guide to IoT Connectivity Solutions for OEMs

We can expect over 75 billion IoT devices to be in operation by 2025. This staggering statistic, a testament to the ever-expanding digital universe, is a clear indicator of the transformative journey that OEMs must undertake to stay ahead.

As we delve into IoT connectivity solutions for OEMs, it becomes evident that embracing this technological evolution is a critical necessity. The convergence of IoT technologies in the OEM sector is reshaping the very fabric of industries, creating smarter, more efficient, and innovative manufacturing processes.

Explore the exciting realm of the Internet of Things in the OEM world, where we will unravel its potential to transform industry standards.

Content

- The Role of OEM IoT Solutions

- IoT Connectivity Solutions for OEMs in Different Sectors

- Network Considerations for OEM Enablement

- Key Considerations for IoT Network Connectivity Solutions

- Best Practices for IoT Implementation in OEM

- Maximising Telemetry Data in IoT

- Understanding Hardware Requirements for IoT in OEMs

- Mastering IoT Connectivity for OEMs with Velos IoT

The Role of OEM IoT Solutions

The integration of IoT in the OEM sector is a significant shift, moving beyond theoretical advantages to practical applications. IoT’s real impact lies in its ability to transform core aspects of OEM operations, including:

- Product design and development

- Manufacturing

- After-sales service

At the forefront of this transformation is product development. IoT integration enables OEMs to design ‘smart’ products equipped with sensors and connectivity, offering real-time data insights.

This shift to data-driven design is a game-changer. It allows for a deeper understanding of customer needs and usage patterns. The shift leads to products that are functionally superior and more aligned with market demands.

The data collected through IoT devices provides invaluable insights into how customers use and interact with products. This information is crucial in tailoring product design to meet specific needs and preferences, enhancing user satisfaction.

IoT also transforms maintenance from a reactive to a proactive process. IoT-enabled devices can predict maintenance needs.

The impact of IoT extends beyond product development to the very heart of manufacturing operations. OEMs can achieve a higher degree of efficiency and responsiveness.

IoT technology offers a real-time view of production lines, enabling OEMs to identify and rectify inefficiencies quickly. This continuous monitoring and adjustment led to:

- Leaner operations

- Reduced waste

- Enhanced productivity

The insights provided by IoT devices revolutionise supply chain management. OEMs gain a more transparent and dynamic understanding of their inventory, facilitating better decision-making and responsiveness to market shifts.

Beyond operational improvements, IoT opens the door to innovative business models. For example, the concept of offering products-as-a-service emerges as a new revenue stream, fostering closer ties with customers and ongoing engagement.

IoT Connectivity Solutions for OEMs in Different Sectors

Across industries, IoT implementation is transforming OEM operations, making them more:

- Efficient

- Responsive

- Customer-centric

As OEMs continue to embrace IoT, we can expect even more groundbreaking advancements and applications in various sectors. The potential applications of IoT in various industries promise enhanced operational efficiency and open up new vistas for product development and customer engagement.

Transforming Automotive Manufacturing with IoT

In the automotive industry, the IoT revolution is reshaping manufacturing processes. Imagine an assembly line where each component is equipped with sensors, feeding real-time data back to the manufacturers. This data-driven approach enables OEMs to fine-tune production lines on the fly.

Beyond the production line, IoT offers a new frontier in vehicle diagnostics and maintenance, allowing for real-time monitoring of vehicle health, potentially transforming the after-sales service landscape.

IoT in Healthcare Equipment Manufacturing

Turning to the healthcare sector, the impact of IoT connectivity solutions for OEMs is equally profound. Here, IoT finds its stride in enhancing the functionality and reliability of medical devices.

From patient monitoring systems to advanced diagnostic tools, IoT-enabled devices can provide continuous data streams, offering invaluable insights into patient health. This improves the quality of care and aids OEMs in tailoring devices to meet the specific needs of healthcare providers and patients.

Revolutionising Agriculture Equipment with IoT

The agricultural sector, too, is ripe for IoT-driven transformation. Powered by IoT, precision agriculture allows for more efficient resource management, from optimising irrigation systems to tailoring fertiliser use based on real-time soil and weather data.

IoT Connectivity solutions for OEMs mean an opportunity to develop smart farming equipment that can significantly boost productivity and sustainability in agriculture.

IoT in Consumer Electronics Manufacturing

In the realm of consumer electronics, IoT is revolutionising the way we interact with everyday devices.

- Smart appliances

- Home automation systems

- Personal gadgets

They are becoming increasingly integrated and intuitive, thanks to IoT.

For OEMs, this translates to an exciting challenge: designing products that seamlessly integrate into the IoT ecosystem and continuously evolve through software updates and user feedback.

Each of these sectors illustrates the broad spectrum of possibilities that IoT offers to OEMs. OEMs can enhance their manufacturing processes and product offerings while also forming stronger connections with their customers.

The data gleaned from IoT devices provides invaluable insights, enabling OEMs to anticipate market trends and customer needs, thereby staying ahead of the curve in innovation and design.

As we progress further into the digital age, the potential applications of IoT in the OEM sector continue to expand, promising a future where smart, interconnected devices become the norm in every industry. The key for OEMs lies in understanding how to harness this potential best to drive:

- Growth

- Innovation

- Customer satisfaction

You may also be interested in the following articles:

Revolutionising Surveillance: IoT Connectivity Solutions for CCTV OEMs

Network Considerations for OEM Enablement

When implementing IoT, one of the most crucial aspects to consider is the network infrastructure. The choice of network affects the performance and reliability of IoT applications. It also has significant implications for:

- Scalability

- Security

- Cost-efficiency

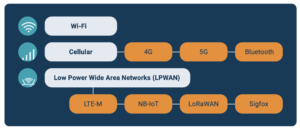

Evaluating Network Types for IoT Connectivity

The first step in establishing an effective IoT network is understanding the various connectivity options available and their suitability for different applications. Common network types include:

Each of these networks offers distinct advantages and limitations.

You may be interested in the below articles:

LTE–M vs NB-IoT explained further

Different LPWAN Technologies Explained

The Most Common LPWAN Use Cases

Wi-Fi is widely used due to its high data transfer speeds and widespread availability. However, its relatively limited range and high power consumption make it less ideal for IoT devices that are mobile or located in remote areas.

Cellular networks, particularly with the advent of 5G, offer extensive coverage and high data speeds. Since 5G, they are quite suitable for IoT applications that require mobility and large data transfers, such as in automotive telematics.

Bluetooth and similar short-range networks are optimal for IoT applications that require low power consumption and short-range connectivity, such as smart home devices.

LPWAN technologies like LTE-M and NB-IoT are designed for long-range communication at a low bit rate, ideal for sensors and actuators spread across vast industrial complexes or agricultural fields.

Balancing Speed, Range, and Power Consumption

Based on their specific IoT application requirements, OEMs must balance speed, range, and power consumption. For instance, high-speed data transmission might be crucial for real-time monitoring systems in manufacturing plants. In contrast, long battery life and wide coverage would be more critical for agricultural IoT sensors.

Security and Reliability in IoT Networks

Security and reliability are paramount in network considerations. IoT networks must ensure secure data transmission to protect sensitive information and prevent unauthorised access. This requires robust encryption protocols and continuous security updates.

Network reliability is essential to maintain consistent data flow and device functionality, particularly in critical applications like healthcare devices or industrial automation.

You may be interested in the below articles:

What is a private APN and how can it help with IoT security?

Top 10 IoT Security Risks and How to avoid them?

Scalability and Future-Proofing

Scalability and future-proofing are key considerations. As IoT ecosystems expand, the network infrastructure must be able to accommodate an increasing number of devices and potentially higher data volumes without compromising performance.

This requires a forward-looking approach, selecting networks that are adequate for current needs and adaptable to future technological advancements and changing application demands.

Selecting the right network for IoT in OEM requires a comprehensive analysis of the specific needs of the application, balancing factors such as:

- Range

- Speed

- Power consumption

- Security

- Scalability

As IoT continues to evolve, staying abreast of emerging network technologies and standards will be crucial for OEMs to leverage the full potential of IoT connectivity.

To learn more about various IoT network technologies, browse our quick guide to IoT Connectivity here.

Key Considerations for IoT Network Connectivity Solutions

Choosing the right network connectivity solution is pivotal. This decision impacts the immediate functionality of IoT applications and shapes long-term scalability and operational efficiency. As OEMs navigate through the myriad of available options, several key factors emerge as critical in the decision-making process.

Beyond basic considerations like data transmission rates and coverage areas, there are several in-depth aspects that OEMs need to scrutinise carefully.

Deep Dive into Data Handling and Management

The choice of a network involves more than assessing its data transmission capacity. OEMs need to consider how different networks manage and prioritise data, especially in environments where vast amounts of data are generated.

For instance, networks like 5G offer advanced data management features. The prioritisation of critical data streams is essential in scenarios demanding rapid decision-making. These can include autonomous vehicle operations or emergency systems in smart factories.

The aspect of latency is crucial for applications requiring real-time processing, such as robotic surgery or instantaneous control of manufacturing machinery. Networks with lower latency, such as 5G, become indispensable in these scenarios.

Comprehensive Coverage Analysis Beyond Basic Range

When it comes to network range and coverage, OEMs should conduct a thorough analysis that goes beyond basic connectivity metrics. OEMs should evaluate how different networks perform in transitioning between indoor and outdoor environments. It is particularly relevant for applications like vehicle tracking systems or mobile industrial equipment.

The geographical location and environmental conditions can significantly influence network performance. For example, in areas with high levels of interference or physical obstructions, certain networks offer more reliable connectivity.

Focusing on Energy Efficiency and Sustainability

In today’s environmentally conscious world, OEMs must consider the energy efficiency and sustainability of their network choices. This is especially pertinent for large-scale IoT deployments, where the cumulative energy usage can have significant environmental impacts.

Networks that are energy-efficient and compatible with renewable energy sources will reduce operational costs. However, it will also align with global sustainability goals.

As OEMs plan their IoT implementations, integrating these considerations into their network selection process will ensure technical and operational efficiency. You are demonstrating a commitment to environmental responsibility.

Balancing Cost with Future-Proofing

Finally, while cost is always a key consideration, OEMs must balance immediate financial outlays with the need to future-proof their IoT networks. This involves assessing the scalability of the network infrastructure and its ability to adapt to future technological advancements.

The goal is to choose a network that fits the current budget and remains viable and efficient as the IoT ecosystem evolves and expands.

Selecting the right IoT network for OEMs is a multifaceted process beyond basic considerations. OEMs can ensure they choose a network solution that meets their immediate needs and is poised to adapt to future developments in the IoT landscape.

Download Prepare for Global IoT deployment white paper (here)

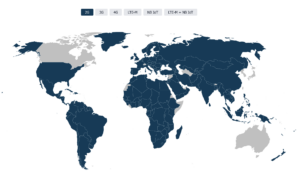

How can you grow your IoT capabilities on a global scale?

With more than 27 billion devices forecast to be connected by 2025, from waste bins to tractors, the Internet of Things offers a huge opportunity for organisations across any vertical.

As a result, according to market analyst firm Statista, the total installed base of IoT units grew from just over 15 billion in 2015 to over 50 billion in 2023. However, in the next two years, that figure is forecast to almost double to over 75 billion units.

IoT enables organisations to streamline operations and drive new revenue through the creation of entirely new applications and services.

Read our white paper to learn how manufacturing organisations and providers can prepare themselves for global IoT deployment at scale.

Best Practices for Implementing IoT Connectivity Solutions for OEMs

The foundation of a successful IoT implementation is a solid strategy that aligns with the company’s overall objectives. OEMs need to thoroughly assess their current processes, identifying potential areas where IoT can bring significant improvements.

This strategic planning should involve setting clear goals, such as:

- Increasing production efficiency

- Enhancing product quality

- Improving customer service

Establishing key performance indicators (KPIs) is also crucial to measure the success of IoT initiatives and ensure they deliver the intended outcomes.

Selecting the Appropriate IoT Platform

Choosing the right IoT platform is a critical decision for OEMs.

The platform should be compatible with the existing technological infrastructure. It should also have the capacity to scale as the company’s IoT needs grow. Selecting a platform that supports various devices and protocols and offers strong data analytics capabilities is important.

Interoperability is a key factor, ensuring the IoT platform seamlessly integrates with other systems and technologies within the organisation. Equally important is the platform’s security features, as protecting sensitive data and maintaining user privacy is paramount in today’s interconnected world.

Download a guide to IoT Connectivity Management Platform (here)

Prioritising Security in IoT Deployments

With the increase in connected devices, prioritising security is essential. OEMs must implement robust security measures to safeguard IoT devices and the data they handle. This includes regular software updates and patches to protect against emerging cyber threats.

Using strong encryption for data transmission and ensuring proper authentication for device access are also critical steps in maintaining a secure IoT environment. OEMs should adopt a proactive approach to security, continually assessing and updating their security practices to address evolving threats.

Emphasising Data Management and Analytics

Effective data management and analytics are at the heart of successful IoT implementations. OEMs need to have a clear plan for how they will handle the vast amounts of data generated by IoT devices.

This involves collecting and storing data and analysing it to glean actionable insights. Data analytics plays a crucial role in unlocking the full potential of IoT, enabling OEMs to:

- Make informed decisions

- Optimise operations

- Innovate product offerings

Effective data management also entails ensuring data quality and integrity, as well as compliance with relevant data protection regulations.

A successful IoT implementation in the OEM sector requires:

- Careful planning

- Selecting the right technology partners

- Prioritising security

- Focusing on effective data management

OEMs can ensure their IoT initiatives are secure and aligned with their business objectives. It paves the way for enhanced:

- Efficiency

- Innovation

- Competitive advantage

Maximising Telemetry Data in IoT

Telemetry data encompasses the automated communication processes by which measurements and other data are collected. They are collected at remote points and transmitted to receiving equipment for monitoring.

Telemetry plays a central role in IoT. In the context of OEMs, this data can include:

- Machine performance metrics

- Environmental conditions

- User behaviour

- Operational efficiency

The real power of telemetry data lies not in its collection but in how it is stored, managed, and visualised to inform strategic decisions.

Strategies for Effective Telemetry Data Management

Effective management of telemetry data begins with efficient data collection. OEMs need to ensure that IoT devices and sensors are strategically placed and calibrated to accurately capture the necessary data.

Once collected, the challenge shifts to storing this massive amount of data. Robust and secure storage solutions are essential, with many OEMs turning to cloud-based solutions for their scalability and ease of access. However, the true value of telemetry data is unlocked through meticulous processing and analysis.

Raw data must be:

- Filtered

- Processed

- Analysed

This is necessary to extract actionable insights. Advanced analytics tools and algorithms play a crucial role in this process, enabling OEMs to discern patterns and trends that inform critical business decisions.

The Power of Data Visualisation in IoT

Data visualisation is a transformative tool in the realm of IoT. It converts complex telemetry data into intuitive, accessible visual formats, making it easier for decision-makers to understand and act upon.

Interactive dashboards are particularly valuable, offering real-time data representation and allowing OEMs to customise views according to specific metrics of interest. This immediacy and clarity of data presentation enhance decision-making.

Data visualisation aids in communicating insights across different departments and stakeholders, ensuring a cohesive understanding and approach to strategic initiatives.

Telemetry data in IoT is a treasure trove of insights for OEMs. Maximising its potential lies in the adept collection, storage, and analysis of this data, paired with effective visualisation techniques. These practices streamline decision-making processes and open avenues for innovation and strategic growth.

As IoT technologies evolve, the ability to harness and interpret telemetry data will become increasingly integral to maintaining a competitive edge in the OEM sector.

Understanding Hardware Requirements for IoT in OEMs

For OEMs venturing into the realm of IoT, comprehending and choosing the right hardware is pivotal. This hardware serves as the backbone of IoT systems, enabling the seamless:

- Collection

- Processing

- Dissemination of data

Sensors and Actuators

At the heart of IoT are sensors, which gather data from their surroundings or machines, be it:

- Temperature

- Pressure

- Motion

- Other metrics

Alongside sensors, actuators play a key role; they respond to the data collected, performing actions like adjusting a valve or moving a machine part. The selection of these components hinges on the specific use case and the nature of the data needed.

IoT Gateways

Acting as intermediaries, gateways bridge the gap between IoT devices and the network. They collect data from various sensors and devices, process it to some degree, and then transmit it to a central server or the cloud.

When selecting gateways, OEMs need to weigh aspects like:

- Data processing capabilities

- Security features

- The range of connectivity options they support

Connectivity Modules

These modules provide the essential link allowing IoT devices to connect to a network. The choice of connectivity hinges on specific requirements such as the desired range, power consumption limits, and the volume of data to be handled.

Processing Units

The processors, or microcontrollers, are the brains of the IoT hardware, responsible for processing the data from sensors before it’s either acted upon locally or sent to the cloud. The required processing power varies depending on the complexity of tasks the device is expected to perform.

Power Sources

In IoT, power management is crucial, particularly for devices placed in remote areas. Options range from batteries to solar power and other energy-harvesting methods, with the choice largely influenced by the device’s power needs and the feasibility of regular maintenance.

Key Considerations in Hardware Selection

The hardware should be capable of scaling up, accommodating an increasing array of devices or sensors as the IoT network expands. It’s vital to ensure that the chosen hardware components are compatible with each other and with the existing systems within the OEM’s infrastructure.

Often deployed in harsh environments, IoT devices must be both durable and reliable, ensuring uninterrupted operation over extended periods. Considering the risks inherent in IoT, selecting hardware with robust security features is crucial to protect against potential breaches and ensure data integrity.

The right hardware is a critical step for OEMs implementing IoT solutions. It requires a careful evaluation of the specific needs of the application to ensure a robust and efficient IoT.

Mastering IoT Connectivity Solutions for OEMs with Velos IoT

As we stand on the brink of a transformative era, the mastery of IoT Connectivity solutions for OEMs emerges as a crucial element for business agility and growth. Velos IoT stands at the forefront of this revolution, offering a best-in-class IoT connectivity management platform that caters to both startups and established service providers.

Whether you are a manufacturer of industrial IoT equipment, IoT-enabled enterprise solutions, or connected consumer electronics, your quality of service is highly dependent on the reliability of your connectivity. Velos IoT is your one-stop-shop connectivity service provider for connecting and managing your devices across the globe.

Partner with Velos IoT to navigate the IoT landscape with a solution that promises business growth, cost efficiency, and an unparalleled customer experience. Learn more about Velos IoT OEM Solutions here.

Download Disruptive OEM Enablement eBook here

Want to know more? Get in touch.

Whether it is a global IoT deployment or a local project, our connectivity solutions are designed to give you the flexibility to scale your business. Contact us to find out how our experts can help